- About Us

-

Business Areas

Business Areas

- Our Technology

- Business Performance

-

Customer Support

Customer Support

Our Technology

A company that values the environment

Condensate Treatment facility

Ammonia and VOCs removal facility

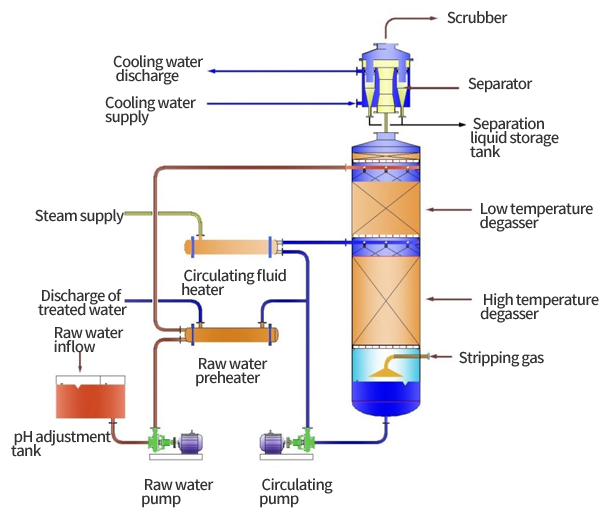

Separation Tower for Low boiling point substances(Separation Tower)

Stripper

- Removal of low-boiling substances mixed with evaporated condensate.

- Mainly removes volatile substances such as NH3, VOC.

- Low boiling substances is degassed by stripping gas (Air)

- To maximize degassing efficiency, Separation Tower are composed of low temperature degassing and high temperature degassing part.

- The degassed low-boiling substances are separated from the separator.

- Materials recovered in the separation liquid can be recycled depending on the composition.

- Reduces the next scrubber load by lowering the degassing gas pollution and temperature.

Main determinants of deaerator efficiency

- pH, temperature, gas volume (air volume), contact efficiency

Expected removal rate by substance

- Ammonia removal rate: about 80% or more

- Methanol removal rate: about 90% or more

- Ethanol removal rate: about 90% or more

- Acetone removal rate: about 85% or more

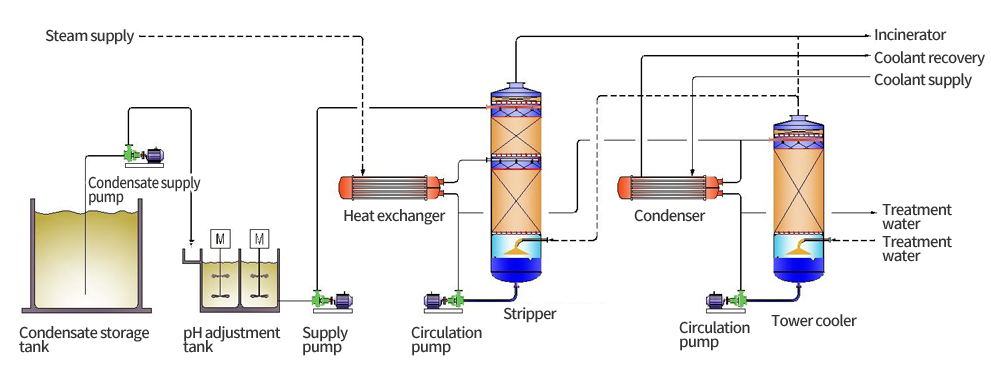

NH3 Stripper

- NH3 Concentration of influent (condensate): : 650 ~ 2,980 ppm

- NH3 Concentration of Stripped water : 5 ~ 63 ppm

- Stripping Gas Flow : 1/300 ~ 1/600

- COD 제거율 : 64 ~ 69%

| pH adjustment tank | Heat exchanger | Stripper | Condenate | Tower Cooler |

|---|---|---|---|---|

|

Adjust the pH of condensate (11.5 or more) NH4 → NH3 change |

Heating of circulating fluid (about 60∼80℃) |

NH3 removal VOC removal |

Primary cooling of condenser treated water (water cooled) (60∼80℃→35℃) |

Secondary cooling (air cooling) (35→32℃) secondary stripping effect of primary treatment |

Kovec Co., Ltd.

Kovec Co., Ltd.