- About Us

-

Business Areas

Business Areas

- Our Technology

- Business Performance

-

Customer Support

Customer Support

Our Technology

A company that values the environment

Evaporation · Concentration

Type of device (classification by energy recovery method)

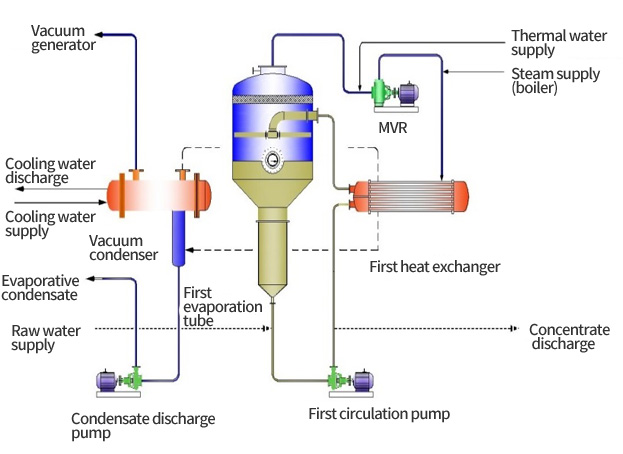

MVR(Mechanical Vapor Recompression)

1EFFECT

- Composed of one heat exchanger and one evaporator.

- Using a heat pump.All of the evaporated waste vapor is sucked and compressed and reused

- About 90% of waste steam is recovered and reused.

- Application review is necessary depending on the characteristics of the waste fluid.

Video of Kovec's Self-Cleaning MVR System, Patented Technology

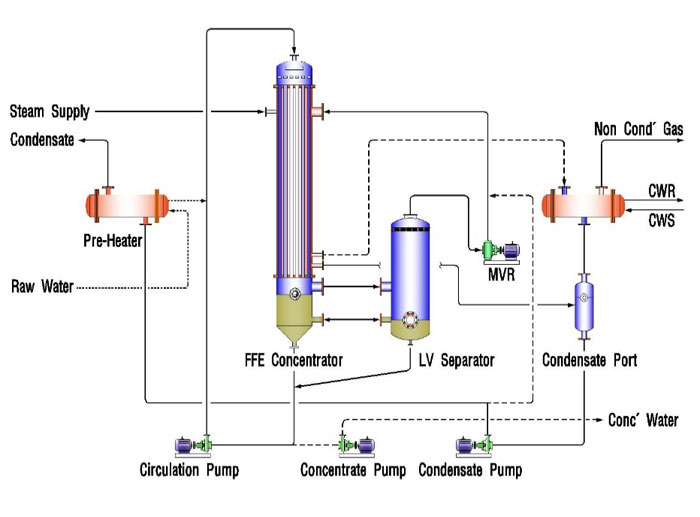

FFE (Fallling Film Evaporation)

FCE (Forced Circulation Evaporation)

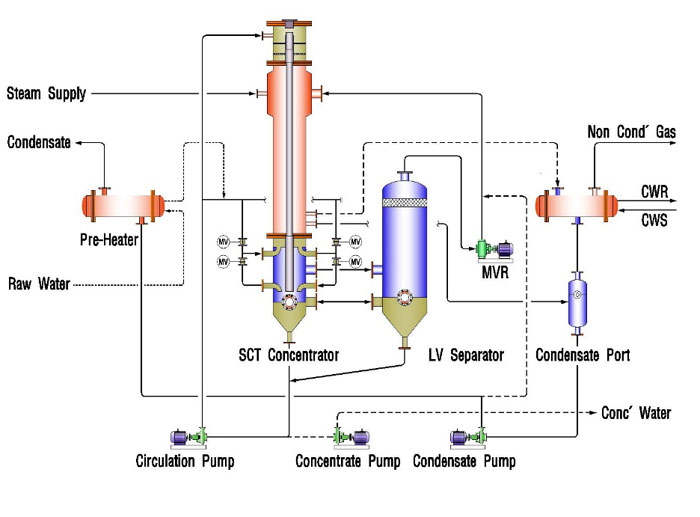

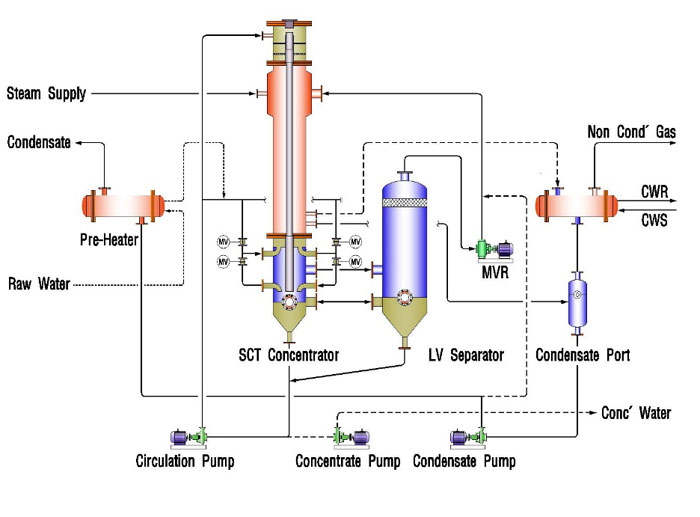

Falling Film type Evaporation with Self Cleaning Technology (Kovec's patented product)

| Type | Falling Film Evaporation (FFE) MVR System | Self Cleaning Technology (SCT) MVR System |

|---|---|---|

| Facility configuration diagram |  |

|

| Features |

|

|

| Pros & Cons |

|

|

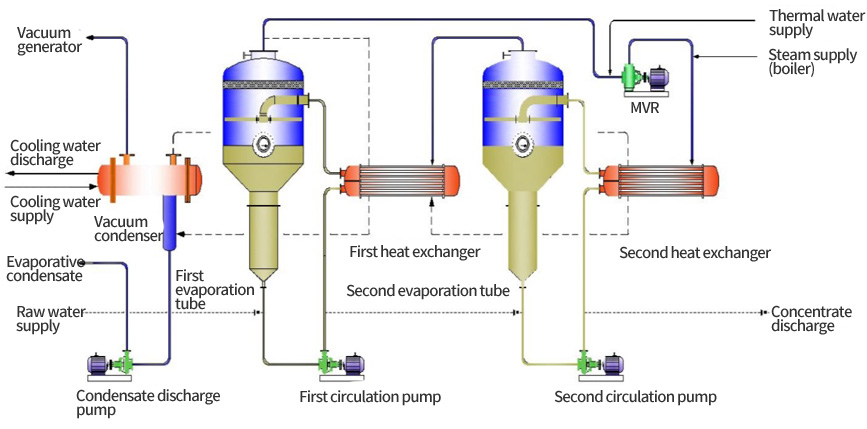

2EFFECT

- 2 Two-stage composed of 2 heat exchangers and 2 evaporators.

- Gereratated waste steam in the second stage is used in the first stage, and all waste vapor generated in the first stage is reused in the second stage after inhaled and compressed.

- About 95% of waste steam is recovered and reused.

- Depending on the BPR(Boiling Point Rising) of the waste liquid, a heat pump with a high compression ratio is required.

Kovec Co., Ltd.

Kovec Co., Ltd.